行业资讯

济南水泥稳定碎石配合比设计实力详解

一、 工程概况

1、 Project Overview

本项目为某地区新建一级公路,设计车速80km/h。根据设计要求,路面基层采用厚度为36cm的水泥稳定级配碎石,分两层施工。为确保基层具有足够的强度、良好的板体性和耐久性,需进行科学的配合比设计。

This project is a new first-class highway in a certain area, with a design speed of 80km/h. According to the design requirements, the pavement base layer is constructed in two layers using cement stabilized graded crushed stone with a thickness of 36cm. To ensure that the grassroots has sufficient strength, good board performance, and durability, scientific mix design is necessary.

工程名称:XX一级公路路面基层工程

Project name: XX first-class highway pavement base course project

结构层:下基层(18cm)+ 上基层(18cm)

Structural layer: Lower base layer (18cm)+Upper base layer (18cm)

设计标准:7天无侧限抗压强度 ≥ 4.0 MPa

Design standard: 7-day unconfined compressive strength ≥ 4.0 MPa

设计依据:

Design basis

1. 《公路路面基层施工技术细则》(JTG/T F20-2015)

1. Technical Guidelines for Construction of Highway Pavement Base (JTG/T F20-2015)

2. 《公路工程集料试验规程》(JTG E42-2005)

2. Test Code for Aggregates in Highway Engineering (JTG E42-2005)

3. 《公路工程无机结合料稳定材料试验规程》(JTG E51-2009)

3. Test Code for Inorganic Bonding Material Stabilized Materials in Highway Engineering (JTG E51-2009)

二、 原材料选择与检验

2、 Raw material selection and inspection

配合比设计的基石是合格的原材料。我们对工程拟采用的原材料进行了全面检测。

The cornerstone of mix design is qualified raw materials. We have conducted a comprehensive inspection of the raw materials to be used in the project.

1. 水泥

1. Cement

品种与标号:采用P.O 42.5级普通硅酸盐水泥。

Variety and grade: P.O 42.5 grade ordinary Portland cement is used.

技术要求:初凝时间应大于3小时,终凝时间应大于6小时且小于10小时,稳定性合格。

Technical requirements: The initial setting time should be greater than 3 hours, the final setting time should be greater than 6 hours and less than 10 hours, and the stability should be qualified.

检测结果:经检测,所选用水泥各项指标均满足规范要求。

Test results: After testing, all indicators of the selected cement meet the specification requirements.

2. 碎石

2. Gravel

料源:本地某石料场生产的石灰岩。

Material source: Limestone produced by a local quarry.

规格:采用4种规格集料进行掺配:

Specifications: Four types of aggregate are used for blending:

1#料(19-31.5mm)

1 # material (19-31.5mm)

2#料(9.5-19mm)

Material # 2 (9.5-19mm)

3#料(4.75-9.5mm)

Material # 3 (4.75-9.5mm)

4#料(0-4.75mm)石屑

4 # material (0-4.75mm) stone chips

技术要求:压碎值≤28%,针片状含量≤18%,软石含量≤5%。

Technical requirements: crushing value ≤ 28%, needle like content ≤ 18%, soft stone content ≤ 5%.

检测结果:对各类集料进行检测,压碎值为22%,针片状含量为12%,均满足规范要求。

Test results: Various types of aggregates were tested, with a crushing value of 22% and a needle like content of 12%, all of which meet the specification requirements.

3. 水

3. Water

采用洁净的饮用水,符合工程用水标准。

Using clean drinking water that meets engineering water standards.

三、 目标配合比设计

3、 Target mix design

步骤一:级配设计

Step 1: Grading Design

根据《JTG/T F20-2015》规范中对水泥稳定碎石基层的级配范围要求,结合本地材料特性,确定目标级配。

According to the grading range requirements for cement stabilized crushed stone base in the JTG/T F20-2015 standard, combined with local material characteristics, the target grading is determined.

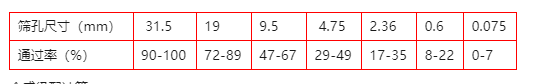

规范中级配范围(基层):

Standardize the scope of intermediate configuration (grassroots):

合成级配计算:

Composite gradation calculation:

通过试验和计算,确定各规格集料的掺配比例。

Determine the mixing ratio of each specification of aggregate through experiments and calculations.

建议比例:1#料 : 2#料 : 3#料 : 4#料 = 25% : 30% : 20% : 25%

Suggested ratio: 1 # material: 2 # material: 3 # material: 4 # material=25%: 30%: 20%: 25%

合成后级配:

Grading after synthesis:

结论:合成级配完全落在规范要求的范围内,且曲线圆滑,属于优良级配。

Conclusion: The composite grading completely falls within the range required by the specifications, and the curve is smooth, belonging to excellent grading.

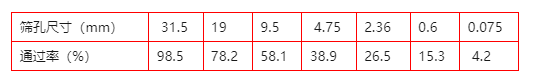

步骤二:确定最佳含水量和最大干密度

Step 2: Determine the optimal moisture content and maximum dry density

采用重型击实试验法。我们选择了4个不同的水泥剂量(3.0%, 3.5%, 4.0%, 4.5%)进行试验。

Adopting the heavy compaction test method. We selected four different cement dosages (3.0%, 3.5%, 4.0%, 4.5%) for the experiment.

试验方法:对每种水泥剂量的混合料,配制5-6个不同含水量的试样进行击实试验,绘制含水量-干密度曲线。

Test method: For each cement dosage mixture, prepare 5-6 samples with different moisture contents for compaction test, and draw the moisture content dry density curve.

试验结果汇总:

Summary of experimental results:

规律:随着水泥剂量的增加,最大干密度略有增大,最佳含水量也相应提高。

Rule: With the increase of cement dosage, the maximum dry density slightly increases, and the optimal moisture content also increases accordingly.

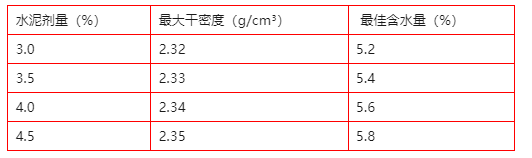

步骤三:无侧限抗压强度试验

Step 3: Unconfined compressive strength test

这是验证配合比是否满足设计要求的核心环节。

This is the core step in verifying whether the mix proportion meets the design requirements.

试件制备:按上述确定的级配、最佳含水量和最大干密度,采用静压法成型Φ150mm × 150mm的圆柱体试件,每个水泥剂量制备13个试件(9个用于强度测定,4个备用)。

Preparation of test specimens: According to the determined grading, optimal moisture content, and maximum dry density, cylindrical specimens with a diameter of 150mm × 150mm were formed using static pressure method. Thirteen specimens were prepared for each cement dosage (nine for strength determination and four for backup).

养护与试验:试件在标准条件下(20±2°C,湿度≥95%)养护6天,浸水1天后,进行无侧限抗压强度试验。

Maintenance and Testing: The specimen is cured for 6 days under standard conditions (20 ± 2 ° C, humidity ≥ 95%), and then immersed in water for 1 day before undergoing unconfined compressive strength testing.

强度结果:

Strength results:

说明:Rd为设计强度4.0MPa,Zα取1.645(保证率95%),Cv为偏差系数(S/Rc)。

Explanation: Rd is the design strength of 4.0MPa, Z α is taken as 1.645 (guarantee rate of 95%), and Cv is the deviation coefficient (S/Rc).

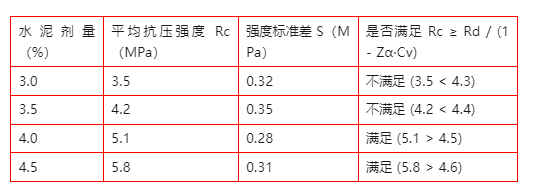

步骤四:目标配合比确定

Step 4: Determine the target mix ratio

经济与技术性比选:

Economic and technological comparison:

水泥剂量4.0%时,强度为5.1MPa,满足设计要求(≥4.0MPa),且有一定富余。

When the cement dosage is 4.0%, the strength is 5.1 MPa, which meets the design requirements (≥ 4.0 MPa) and has a certain margin.

水泥剂量4.5%时,强度更高,但水泥用量增加,不经济,且水泥剂量过高易导致干缩裂缝增多。

When the cement dosage is 4.5%, the strength is higher, but increasing the cement dosage is uneconomical, and excessive cement dosage can easily lead to an increase in shrinkage cracks.

最终确定目标配合比:

Final determination of target mix ratio:

集料比例: 1#料 : 2#料 : 3#料 : 4#料 = 25 : 30 : 20 : 25

Aggregate ratio: 1 # material: 2 # material: 3 # material: 4 # material=25:30:20:25

水泥剂量: 4.0% (外掺法,即水泥质量占干集料总质量的百分比)

Cement dosage: 4.0% (external mixing method, i.e. the percentage of cement mass to total dry aggregate mass)

最大干密度: 2.34 g/cm?

Maximum dry density: 2.34 g/cm?

最佳含水量: 5.6%

Best moisture content: 5.6%

四、 生产配合比验证与施工控制

4、 Production mix ratio verification and construction control

1. 生产配合比验证:在目标配合比确定后,应在拌和站进行试拌。对热料仓的集料进行筛分,调整冷料仓的进料比例,确保生产出的混合料级配与目标级配基本一致。

1. Production mix proportion verification: After the target mix proportion is determined, trial mixing should be carried out at the mixing station. Screen the aggregate from the hot material bin, adjust the feeding ratio of the cold material bin, and ensure that the produced mixture has a gradation that is basically consistent with the target gradation.

2. 施工控制要点:

2. Key points of construction control:

含水量控制:施工时混合料的含水量应略高于最佳含水量0.5%~1.0%,以补偿运输和摊铺过程中的水分损失,通常控制在6.0%~6.5%。

Moisture content control: During construction, the moisture content of the mixture should be slightly higher than the optimal moisture content by 0.5% to 1.0% to compensate for moisture loss during transportation and paving, usually controlled at 6.0% to 6.5%.

拌和均匀性:确保水泥分布均匀,无灰条、花白料。

Uniformity of mixing: Ensure that the cement is evenly distributed without any gray strips or white materials.

压实:及时碾压,采用合理的压实工艺(如静压+弱振+强振+胶轮收面),确保压实度达到98%以上。

Compaction: Timely compaction, using reasonable compaction techniques (such as static pressure+weak vibration+strong vibration+rubber wheel finishing) to ensure a compaction degree of over 98%.

养护:碾压完成后立即覆盖土工布或洒水养护,保持表面湿润,养护期不少于7天。

Maintenance: Immediately cover with geotextile or sprinkle water for maintenance after compaction, keep the surface moist, and the maintenance period is not less than 7 days.

五、 结论

5、 Conclusion

通过本实例,我们系统性地完成了水泥稳定级配碎石的配合比设计。最终确定的配合比为:集料比例25:30:20:25,水泥剂量4.0%,最佳含水量5.6%,最大干密度2.34 g/cm?。该配合比不仅满足了设计强度要求,也兼顾了材料的抗裂性和经济性,为后续的大规模施工提供了可靠的技术依据。在实际施工中,必须根据原材料波动和天气情况,对含水量等参数进行动态微调,以确保工程质量万无一失。

Through this example, we systematically completed the mix design of cement stabilized graded crushed stone. The final determined mix ratio is: aggregate ratio of 25:30:20:25, cement dosage of 4.0%, optimal moisture content of 5.6%, and maximum dry density of 2.34 g/cm ??. This mix ratio not only meets the design strength requirements, but also takes into account the material's crack resistance and economy, providing a reliable technical basis for subsequent large-scale construction. In actual construction, it is necessary to dynamically adjust parameters such as moisture content based on fluctuations in raw materials and weather conditions to ensure the quality of the project is foolproof.

本文由 济南水泥稳定碎石 友情奉献.更多有关的知识请点击 http://www.ycgjglcl.com/ 真诚的态度.为您提供为全面的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from Jinan Cement Stabilized Crushed Stone For more related knowledge, please click http://www.ycgjglcl.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Stay tuned

公司地址:济南市商河县贾庄镇民营经济创业园

公司地址:济南市商河县贾庄镇民营经济创业园 公司名称:永诚广建公路材料(山东)有限公司

公司名称:永诚广建公路材料(山东)有限公司  备案号:

备案号: